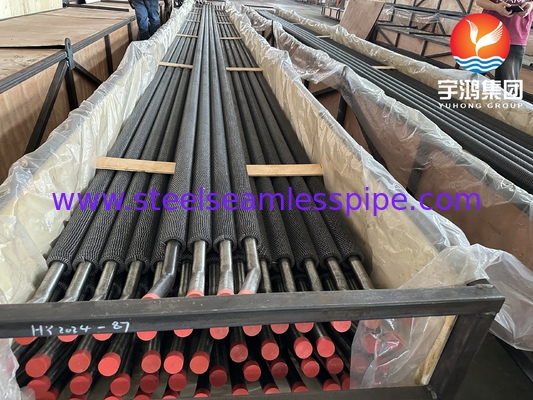

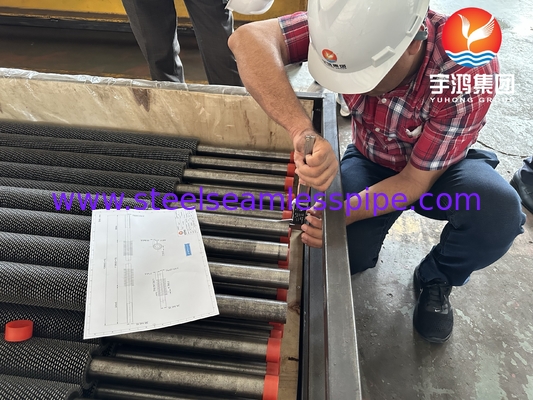

ASME SA213 T22 Tubi a pinne serrate in acciaio legato HFW per progetti di raffinerie

ASME SA213 Specifica per caldaie di acciaio in lega ferritica e austenitica senza saldature, supercaldaie e tubi per scambiatori di calore.Fabbricazione e condizione I tubi devono essere fabbricati con il processo senza cuciture e devono essere finiti a caldo o a freddo, come specificato.

Iltubi a pinne segheè una forma speciale e importante di tubo a pinne a spirale saldo ad alta frequenza/HFW. Prima che la striscia di acciaio utilizzata per le pinne subisca saldatura ad alta frequenza, viene tagliata ad una certa altezza e profondità.Durante il processo di avvolgimento e saldatura sul tubo di baseGli esperimenti e i documenti pertinenti hanno dimostrato che, a causa delle pinne dentate, la perturbazione del flusso d'aria è aumentata,che aumenta il trasferimento di calore e favorisce lo scarico di polveri accumulate.

Materiali di tubi e pinnepossono essere di acciaio di lega carbonica, ferritica o austenitica e possono essere di combinazioni di materiali simili o diverse.

Composizione chimica max %

| Grado |

Carbonio |

Fabbricazione a partire da: |

Fosforo |

Sulfuro |

Silicio |

Cromo |

Acido di potassio |

| T22 / K21590 |

0.05-0.15 |

0.30-0.60 |

0.025 |

0.025 |

0.50 |

1.90-2.60 |

0.87-1.13 |

Proprietà meccaniche

| Grado |

Resistenza alla trazione, min. |

Forza di resa, min. |

Allungamento (%) |

Durezza, Max. |

| T22 / K21590 |

60ksi,415MPa |

30ksi,205MPa |

30 |

163 HB/170 HV |

85 HRB |

Applicazione dei progetti chiave

The alloy steel high-frequency welding / HFW serrated finned tube is a heat transfer component specifically designed for use in high-temperature and corrosive environments within oil refineries projectsLe pinne dentate possono creare turbolenze e rompere gli strati termicamente limitanti.

Treni per il riscaldamento di petrolio greggio --- in scambiatori di precalore per riscaldare il petrolio greggio prima della distillazione

Nota speciale: l'acciaio legato (ad esempio, T5, T9, T11, T22, P5, P9, P11, P22, P91) resiste alla corrosione ad alta temperatura da zolfo e greggio acido

Unità di trattamento idrico (HPU) --- negli scambiatori di alimentazione/effluenti e nei riscaldatori di carica dei reattori

Punto speciale:resistente a ambienti ad alta pressione di idrogeno (idrotrattamento e idrocracking)

Unità di congelamento ritardato --- nei tubi di riscaldamento del coke e nei sistemi di recupero del calore di scarico

Punto speciale: rresistente al coke e al ciclo termico a causa della composizione dell'acciaio legato

Unità di cracking catalitico a fluidi (FCC) --- nei pre riscaldatori di aria a rigeneratore e nelle caldaie di recupero del calore dei gas di combustione

Punto speciale: heles gas di combustione ad alta temperatura (fino a 700°C/1300°F) / L'acciaio legato resiste all'erosione delle particelle del catalizzatore

Unità di recupero dello zolfo (SRU) --- nelle caldaie di calore di scarico e nei condensatori delle unità di processo Claus

Punto speciale:resistente alla corrosione da zolfo (H2S, SO2, SO3)

Reboilers & Condensers --- in reboilers di amine (eliminazione di H2S) e condensatori aerei

Punto speciale:acciaio legato resistente alla corrosione da amine e allo stress cracking

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!