ASTM A312 TP304H Tubo a pinna serrata

Specifica del materiale (ASTM A312 TP304H):

ASTM A312: Norma per tubi in acciaio inossidabile austenitici senza saldatura/saldati utilizzati in ambienti ad alta temperatura e corrosivi.

TP304H: un grado di A312, che indica "Tipo 304 ad alto tenore di carbonio". La composizione comprende 18% Cr, 8% Ni e 0,04 ∼0,10% C. Il tenore elevato di carbonio aumenta la resistenza al sollevamento ad alte temperature,ideale per applicazioni a temperature superiori a 525°C.

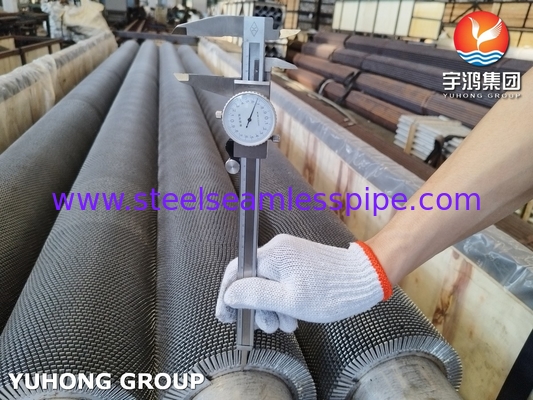

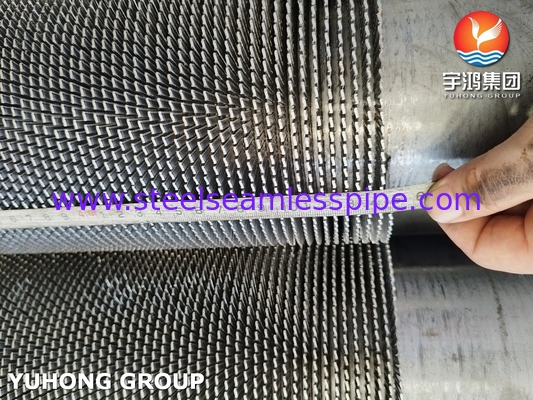

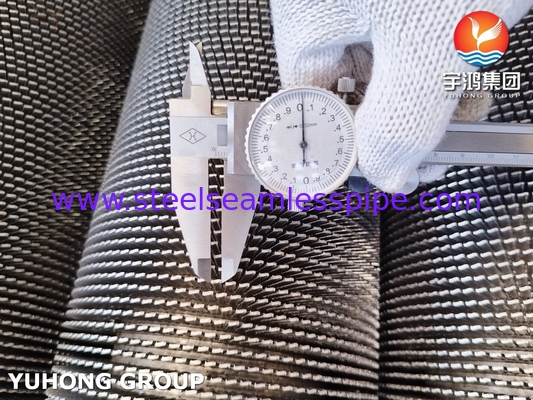

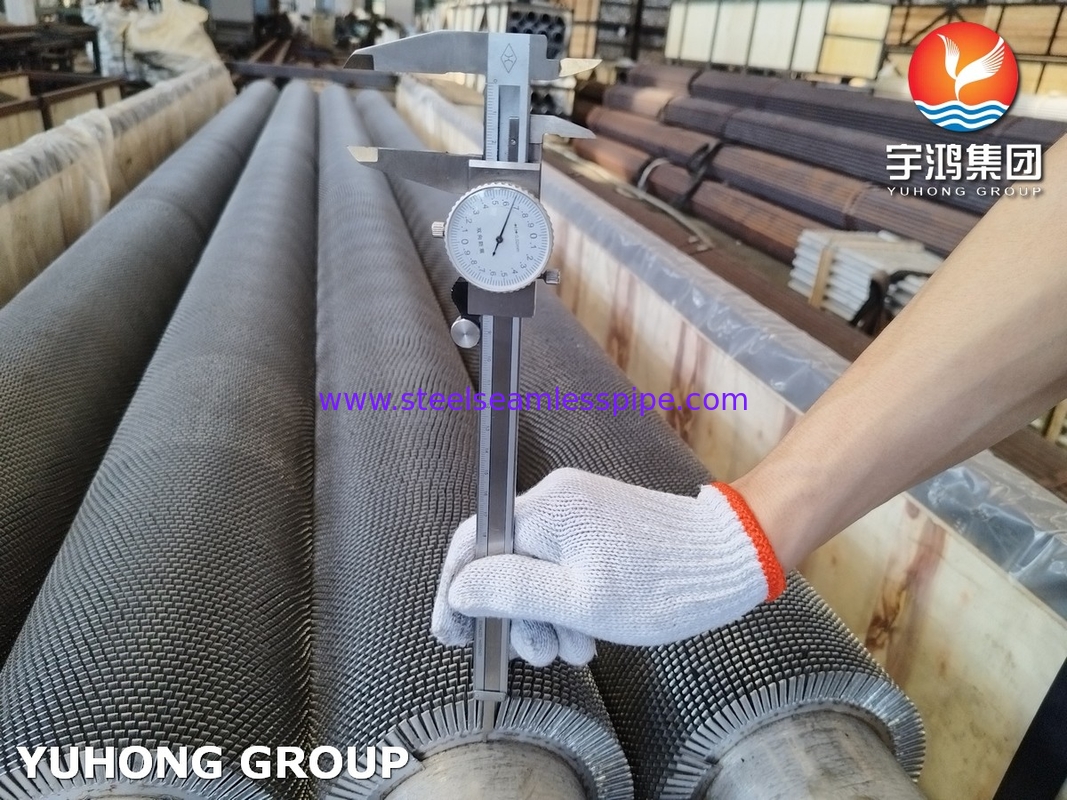

Caratteristiche di progettazione (tubo a pinna serrata):

Struttura delle pinne: le pinne dentate aumentano l'area superficiale e interrompono gli strati di confine del fluido, aumentando la turbolenza e l'efficienza del trasferimento di calore rispetto alle pinne lisce.

Fabbricazione: le pinne sono in genere saldate, estruse o lavorate sul tubo di base, con serrature formate durante o dopo l'attacco delle pinne.

Applicazioni:

Comune nelle industrie che richiedono uno scambio termico efficiente in condizioni difficili: generazione di energia (caldaie, supercaldaie), impianti petrolchimici, raffinerie e sistemi HVAC.

Adatto a servizi ad alta temperatura come la generazione di vapore, sistemi di gas di scarico e unità di recupero del calore.

Vantaggi:

Miglioramento del trasferimento di calore: le serrature migliorano le prestazioni termiche fino al 30% rispetto alle pinne semplici.

Durabilità: la resistenza alla corrosione del TP304H e la sua resistenza alle alte temperature garantiscono una lunga durata in ambienti aggressivi.

Riduzione dell'inquinamento: la turbolenza delle serrature può ridurre la deposizione di particolato.

Considerazioni:

Caduta di pressione: l'aumento della turbolenza può aumentare la perdita di pressione del sistema, influenzando i costi di pompaggio.

Costo: maggiori spese di materiale e di fabbricazione rispetto ai tubi non serrati o di qualità inferiore.

Manutenzione: È essenziale controllare regolarmente l'integrità delle pinne, la corrosione e i blocchi.

Installazione e compatibilità:

Compatibile con la saldatura e con i raccordi standard; assicurare la compatibilità con la chimica dei fluidi (ad esempio, rischi di esposizione ai cloruri per il 304H).

La progettazione deve tener conto dell'espansione termica e dello stress meccanico per evitare il distacco delle pinne.

Conclusione: i tubi a pinna serrata ASTM A312 TP304H sono ottimizzati per un trasferimento di calore ad alta efficienza in contesti difficili, bilanciando i guadagni di prestazione con i costi operativi.La selezione dovrebbe dare la priorità all'ambiente, requisiti termici e manutenzione del ciclo di vita.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!