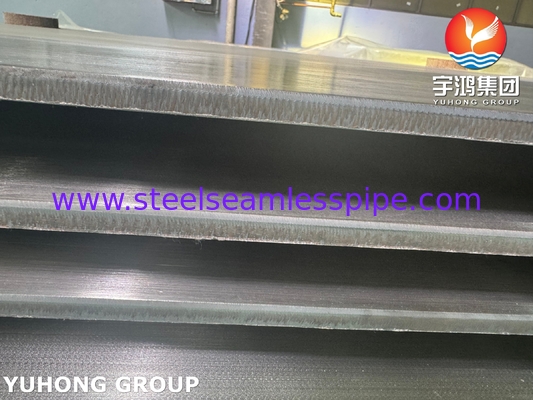

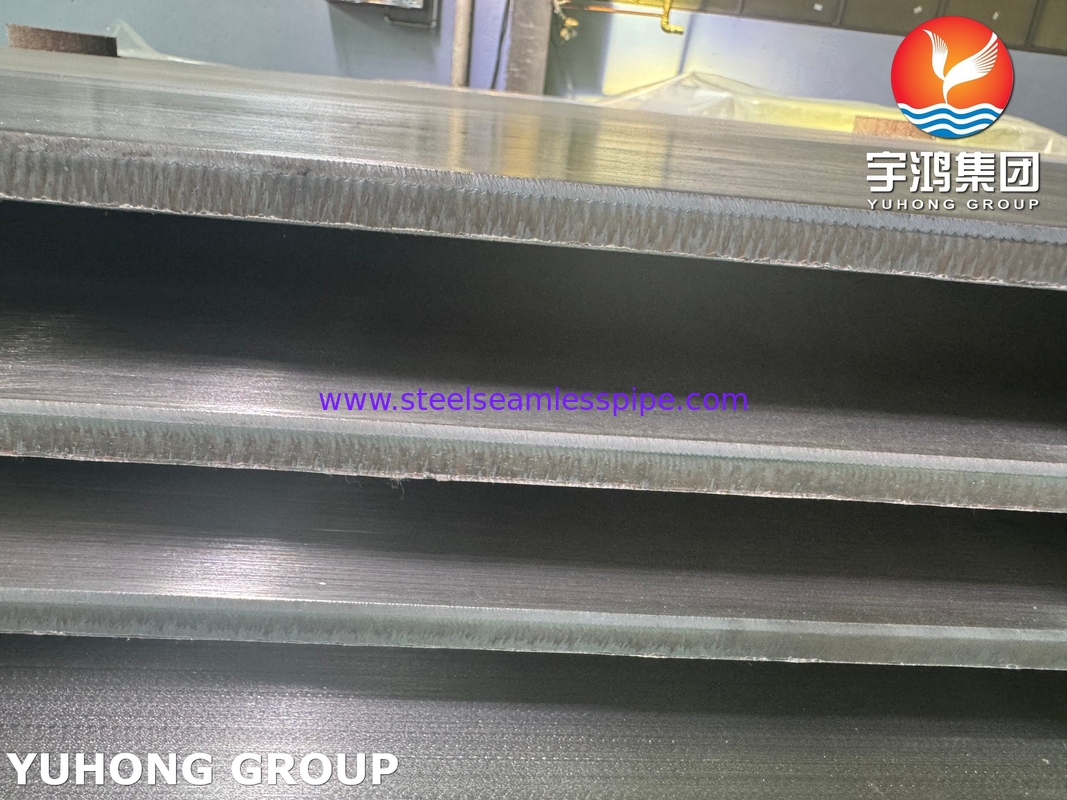

PANELLA di rivestimento in acciaio al carbonio A516 GR.70 CON N04400 rivestimento di un lato

Placca di acciaio composito esplosivo (placca di acciaio rivestita saldata per esplosione)

La piastra di acciaio composito esplosivo, nota anche come piastra placcata saldata a esplosione, è un materiale ad alte prestazioni creato legando due o più metalli dissimili utilizzando la detonazione controllata.Questo processo forma un legame metallurgico senza alterare significativamente le proprietà dei metalli comuni.

1Come funziona il rivestimento esplosivo

Il processo prevede:

- Piastra di base (metallo di supporto): in genere acciaio al carbonio (ad esempio, A516 Gr.70) o acciaio a bassa lega.

- Strato placcato (metallo resistente alla corrosione): Monel 400 (N04400), acciaio inossidabile, titanio o leghe di nichel.

- Materiale esplosivo: un esplosivo ad alta energia (es. RDX o nitrato di ammonio) viene posto sullo strato rivestito.

- Detonazione: quando si accende, l'esplosione crea una pressione estrema (fino a 10 GPa) e una velocità elevata (centinaia o migliaia di m/s), costringendo i due metalli a scontrarsi ad un angolo,creare un legame metallurgico.

2. Vantaggi delle piastre con rivestimento esplosivo

Forte legame: resistenza al taglio superiore a quella del rivestimento legato a rotoli o sovrapposto a saldatura.

Ampie combinazioni di materiali: compatibile con metalli altrimenti difficili da saldare (ad esempio acciaio + titanio, acciaio + rame).

Nessuna fragilità intermetallica: a differenza della saldatura a fusione, la saldatura a esplosione evita fasi dannose.

Flessibilità dello spessore: lo strato rivestito può variare da 1 mm a 30 mm.

Risparmio economico: si risparmiano le leghe costose utilizzandole solo dove sono necessarie.

3. Applicazioni delle piastre composite esplosive

- Petrolio e gas: navi a pressione, condotte, piattaforme offshore.

- Processo chimico: reattori, scambiatori di calore, serbatoi di accumulo di acidi.

- Centrali elettriche: sistemi FGD, condensatori.

- Marina e desalinizzazione: attrezzature per il trattamento dell'acqua di mare.

- Aerospaziale e Difesa: corazza leggera, componenti per razzi.

| Metodo |

Saldatura da esplosivo |

Sovrapposizione di saldatura |

| Forza del legame |

Molto elevato |

Moderato-alto |

| Opzioni materiali |

Molto ampia |

Limitato |

| Input di calore |

Nessuna (processo a freddo) |

Molto elevato |

| Costo |

Medio-alto |

Alto (lavoro) |

| Controllo dello spessore |

Eccellente. |

Poveri (disuguali) |

5. Combinazioni di esplosivi comuni

- Acciaio carbonio + acciaio inossidabile (304/316)

- A516 Gr.70 + Monel 400 (N04400)

- Acciaio + Titanio (Gr.2/Gr.5)

- Acciaio + leghe di rame/nickel

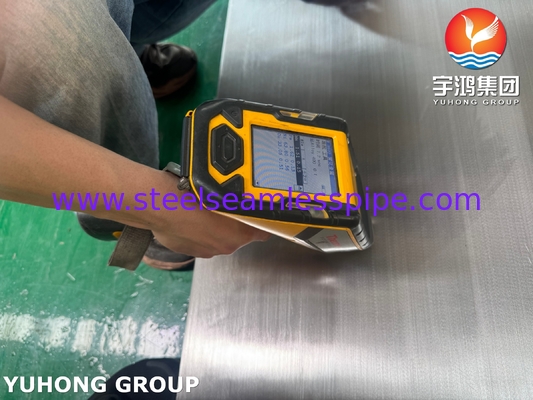

6. Norme e prove

- ASTM B898 (piastre placcate soldate a esplosione)

- ASME SA264 (placca in acciaio inossidabile)

- ISO 23206 (saldatura esplosiva)

- Test non distruttivi (NDT): test ad ultrasuoni (UT), radiografia (RT).

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!