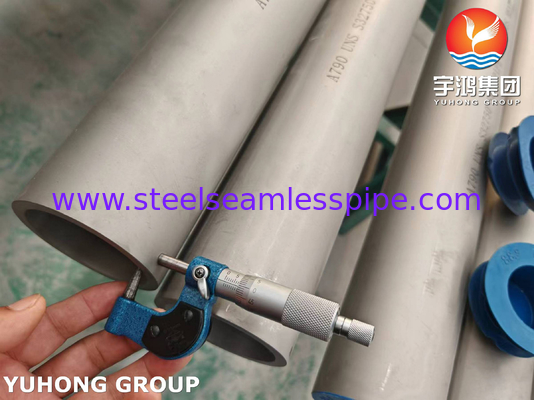

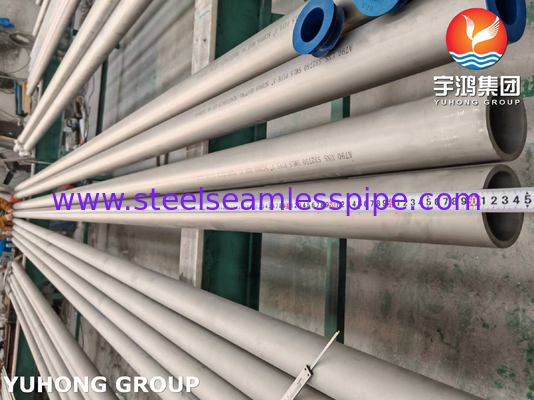

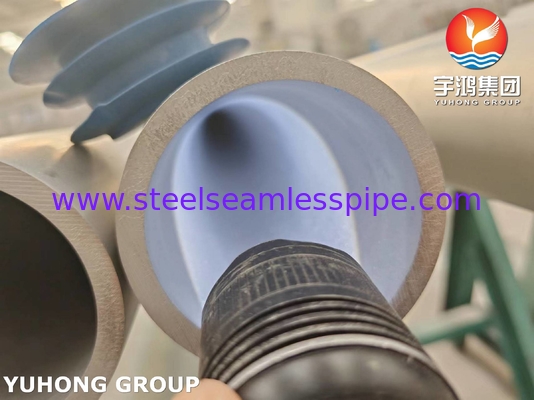

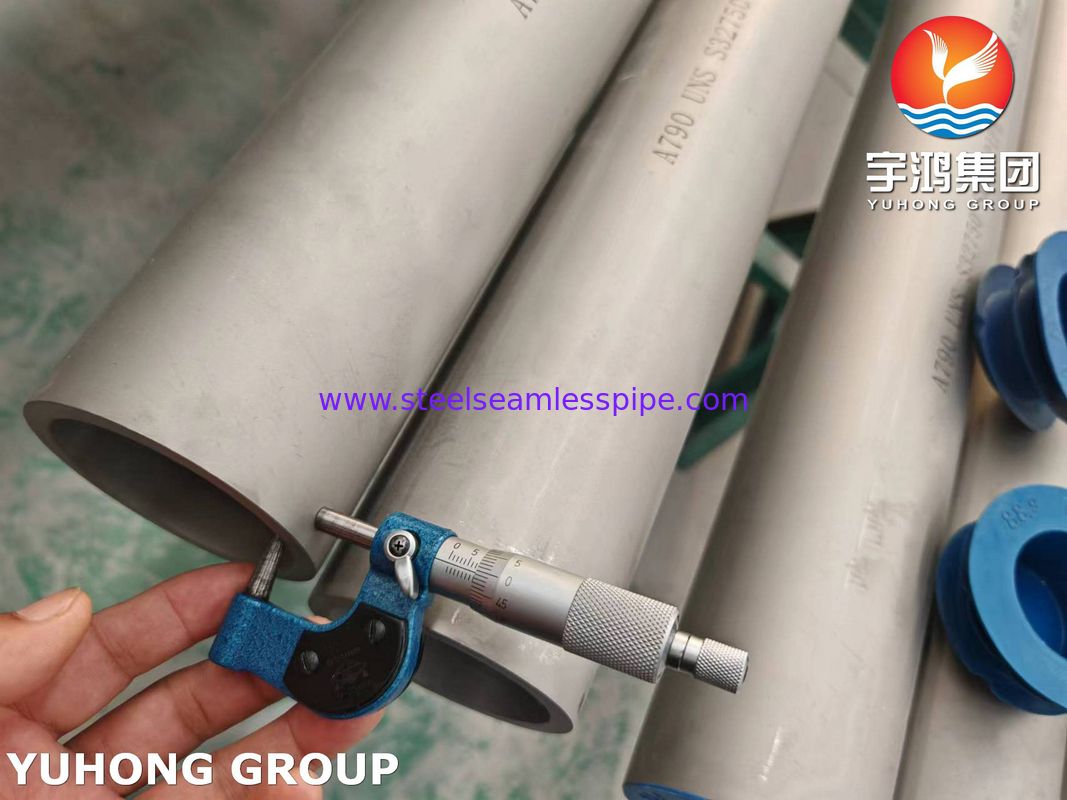

ASTM A790 UNS S32750 Super Duplex Steel Pipe

S32750 super duplex stainless steel is designed for demanding environments, offering excellent strength, toughness, and corrosion resistance. It exhibits exceptional resistance to pitting and crevice corrosion in chloride environments. It exhibits good corrosion resistance against a wide range of inorganic and organic acids and is also resistant to alkaline media to a certain extent.

It is important to note that S32750 is not recommended for prolonged exposure to temperatures exceeding 570°F (approximately 300°C). Its high nitrogen content contributes to corrosion resistance and strength, but it typically contains only minimal or no copper and tungsten compared to S32760.

Super duplex stainless steel UNS S32750 (F53 / 1.4501) offers excellent resistance to localized corrosion in seawater and other chloride-containing media, with a critical pitting temperature (CPT) typically exceeding 50°C. Compared to conventional austenitic stainless steel and 22% chromium duplex steel, S32750 offers higher strength and good resistance to stress corrosion cracking, making it suitable for a variety of industrial fields such as chemical, oil and gas, marine and energy. The alloy complies with NACE MR0175/ISO 15156 standards, is suitable for sour environments, and has been approved by ASME for pressure vessel manufacturing.

Chemical Composition

| A790 S32750 Chemical Composition(%) |

| Element |

C |

Si |

Cr |

Mn |

P |

Ni |

Mo |

| Range |

≤0.030 |

≤0.80 |

24.00-26.00 |

≤1.20 |

≤ 0.035 |

6.00-8.00 |

3.00-4.00 |

Mechanical Properties

| A790 S32750 Mechanical Properties |

| Tensile Strength |

Yield Strength |

Hardness |

Elongation |

| ≥795MPa |

≥550MPa |

≤ 310HB |

25-35% |

Equivalent Material of UNS S32750 (Super Duplex 2507)

| UNS |

EN (Material Number) |

EN (Grade Designation) |

ASTM |

ASME |

DIN |

| S32750 |

1.440 |

X2CrNiMoN25-7-4 |

A790 S32750 |

SA790 S32750 |

1.4410 |

Main Features of ASTM A790 S32750 Super Duplex Steel Pipe

1.Very Strong & Hard: It is much stronger than common stainless steels. This allows for making equipment with thinner walls, saving weight and cost.

2.Great Corrosion Resistance: It performs exceptionally well in harsh environments, especially against pitting and cracking in saltwater and chemicals containing chlorides.

3.Good Value: It offers a mix of strength and corrosion resistance that is often better than many other stainless steels and more affordable than high-end nickel alloys.

Applications for ASTM A790 S32750 Super Duplex Steel Pipe

1.Oil & Gas: Underwater pipes, process systems, and equipment handling salty water and sour gases.

2.Chemical Processing: Transporting highly corrosive acids, salts, and chemicals in reactors, heat exchangers, and process piping systems.

3.Seawater Systems: Pipes for seawater cooling, firefighting, and desalination plants.

4.Power & FGD Industry:Flue Gas Desulfurization (FGD) systems in power plants to handle corrosive scrubber environments.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!