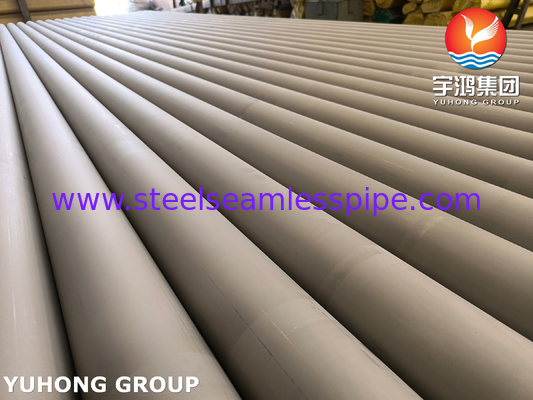

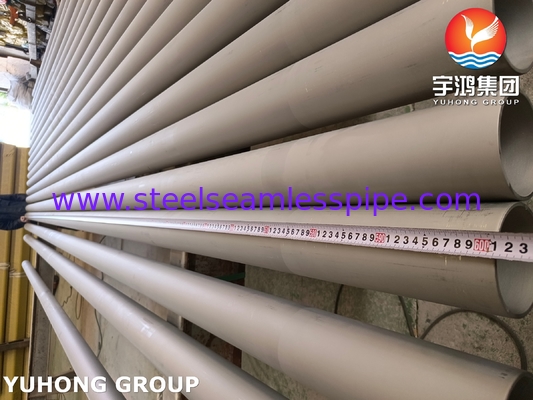

ASTM A312 TP304L Stainless Steel Seamless Pipe Pickled and Annealed for Oil and Gas

ASTM A312 is the ASTM standard specifically for "austenitic stainless steel seamless and welded nominal pipe." It specifies a series of technical specifications for this type of steel pipe, including dimensions, tolerances, mechanical properties, chemical composition, pressure requirements, and test methods. TP304 is the most classic and common austenitic stainless steel grade, often referred to as 18-8 stainless steel. The "L" stands for "Low Carbon," referring to ultra-low carbon.

According to ASTM A312, TP304L steel pipes must undergo hydrostatic testing to verify their overall strength and tightness, ensuring they will not leak or rupture under operating pressure. Eddy current testing can also be used in place of hydrostatic testing upon request. If the customer requires other testing, ultrasonic testing or radiographic testing can be selected.

What are the excellent properties of ASTM A312 TP304L stainless steel seamless pipe?

1. Excellent corrosion resistance: 18% chromium forms a dense and durable chromium oxide film on the surface of TP304L stainless steel pipe, effectively resisting corrosion from air, water, various chemicals, and food media. This makes TP304L stainless steel seamless pipe exhibit superior corrosion resistance to most common steels.

2. Extremely strong resistance to intergranular corrosion: This is the key difference between 304L and standard 304. By significantly reducing the carbon content, 304L fundamentally reduces the tendency for chromium carbide precipitation, making it particularly suitable for welding processes and applications where post-weld heat treatment is not possible, thus avoiding the risk of corrosion in the weld area.

3. Excellent mechanical properties and workability: Its high strength and good toughness make it easy to bend, form, and other processes.

4. Excellent low-temperature toughness: Its austenitic structure enables TP304L stainless steel to maintain good impact toughness even at low temperatures, making it suitable for low-temperature environments.

5. Good high temperature performance: TP304L stainless steel can maintain high strength and oxidation resistance at high temperatures, but its operating temperature is limited.

ASTM A312 TP304L Stainless Steel Seamless Pipe Chemical Composition

| SS GRADE |

ASTM A312 CHEMICAL COMPOSITION % MAXIMUM |

| C |

MN |

P |

S |

SI |

CR |

NI |

MO |

TI |

| TP304L |

0.035 |

2.00 |

0.045 |

0.030 |

1.00 |

18.0-20.0 |

8.0-13.0 |

--- |

--- |

ASTM A312 TP304L Stainless Steel Seamless Pipe Mechanical Properties

| SS GRADE |

HEAT TREATMENT |

Tensile Strength, min ksi [MPa] |

Yield Strength, min ksi [MPa] |

|

| TP304L |

Solution |

70 [484] |

25 [170] |

ASTM A312 TP304L Stainless Steel Seamless Pipe Application

- Chemical and petrochemical industries: transport of various chemical media, process piping, and heat exchanger tubes.

- Energy and power industries: boiler tubes and heat exchanger tubes in power plants.

- High- and low-temperature services: such as heat exchangers (high temperature) and liquefied gas transport (low temperature).

- Food and beverage industries: Due to its corrosion resistance and easy cleanability, it is commonly used in process piping systems in breweries, dairies, and pharmaceutical plants.

- Pharmaceutical and biotechnology industries: process systems and pure water piping with extremely high requirements for cleanliness and corrosion resistance.

- Shipbuilding and marine engineering: seawater cooling systems and ship piping.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!