1Applicazioni

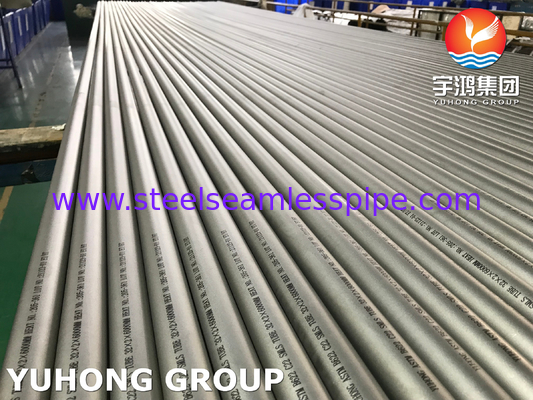

I tubi senza cuciture ASTM B622 C22 (Hastelloy C-22) sono utilizzati in ambienti estremi che richiedono resistenza alla corrosione, stabilità ad alte temperature e affidabilità meccanica:

Reattori, colonne di distillazione e condotte per la movimentazione di acidi solforico, cloridrico e nitrico.

Scambiatori di calore nei sistemi di raffreddamento ricchi di cloruri (ad esempio acqua di mare o salamoia).

Tubi per tubi, ombelici sottomarini e valvole in ambienti di gas acidi (H2S).

Flare stacks e condensatori nelle raffinerie.

Bioreattori sterili e sistemi CIP/SIP (clean-in-place/steam-in-place).

attrezzature per il ritrattamento dei combustibili esposti all'acido nitrico e allo stoccaggio dei rifiuti radioattivi.

Tubi per la combustione delle turbine a gas, tubi geotermici di salamoia e tubi per caldaie.

Fabbricazione di eliche marine, linee idrauliche aerospaziali e strumenti per la fabbricazione di semiconduttori.

2Forza.

- Proprietà meccaniche (per ASTM B622):

Resistenza alla trazione: ≥ 690 MPa (100 ksi)

Forza di potenza: ≥ 310 MPa (45 ksi)

L'allungamento: ≥ 45% (assicura la duttilità per la moltiplicazione/saldatura).

Durezza: ≤ 100 HRB (scala Rockwell B).

(1) Resistenza alla corrosione:

Resiste alla corrosione da crepe, a crepe e alla crepa da corrosione da stress (SCC) in cloruri, solfuri e acidi misti (ad esempio HCl + FeCl3).

Performance in ambienti sia ossidanti (ad esempio HNO3) che riducenti (ad esempio H2SO4).

(2) Performance a temperatura:

Mantenere la resistenza da criogenica (-196°C) fino a 600°C (1112°F).

Resiste all'ossidazione e alla carburizzazione in ambienti ad alta temperatura.

(3) Integrità della pressione:

La costruzione senza saldature consente l'uso in sistemi ad alta pressione (ad esempio, linee idrauliche, pozzi di petrolio HPHT).

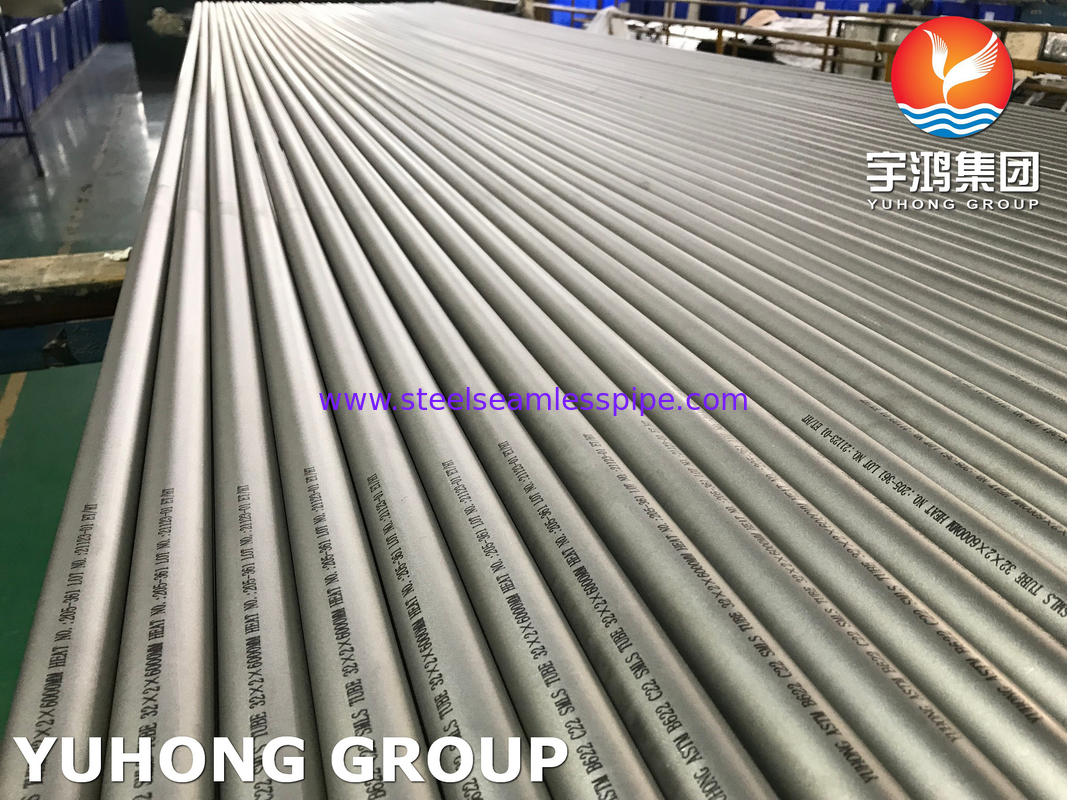

3. Processo di produzione

La lega grezza UNS N06022 (Ni-Cr-Mo-W) è fusa sotto vuoto per garantire purezza e omogeneità.

Estrussione: le lastre riscaldate vengono forzate attraverso una matrice per formare tubi cavi.

Perforazione rotante: i biglietti solidi vengono perforati con un mandrello per creare tubi senza cuciture.

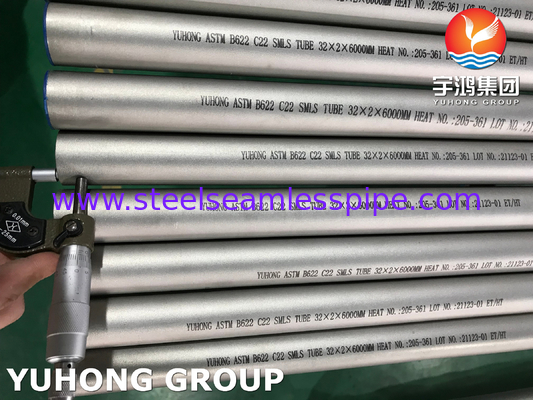

Il disegno a freddo o il laminare migliora la precisione dimensionale e la finitura superficiale.

Il ricottamento in soluzione a 1120-1175 °C (2050-2150 °F) seguito da un'accezione rapida per sciogliere le fasi secondarie e ripristinare la resistenza alla corrosione.

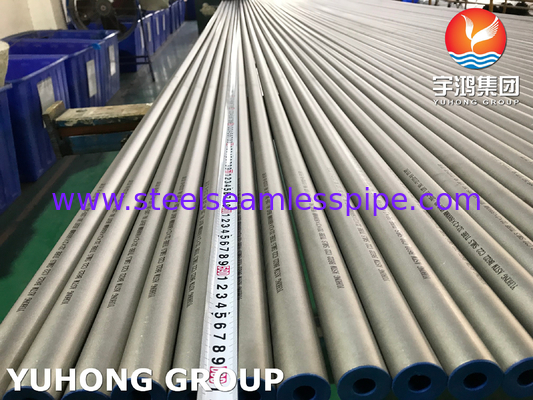

Decolorazione con acido nitrico/idrofluorico per rimuovere gli strati di ossido.

Polire (facoltativo) per applicazioni igieniche o di alta purezza.

4Controllo della qualità:

Prova non distruttiva (NDT): prova di corrente eddy, ultrasonica o idrostatica per rilevare difetti.

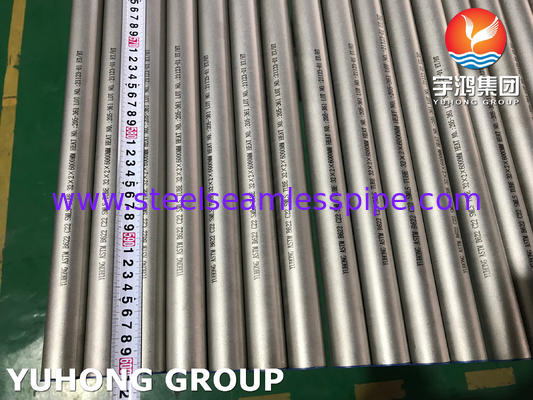

Certificazione: i rapporti di prova del mulino (MTR) verificano la conformità all'ASTM B622 per la chimica, le proprietà meccaniche e le dimensioni.

Principali vantaggi della costruzione senza cuciture:

Nessuna saldatura = nessun punto debole, ideale per applicazioni ad alta pressione/temperatura.

La struttura uniforme del grano aumenta la resistenza alla corrosione e la durata della fatica.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!