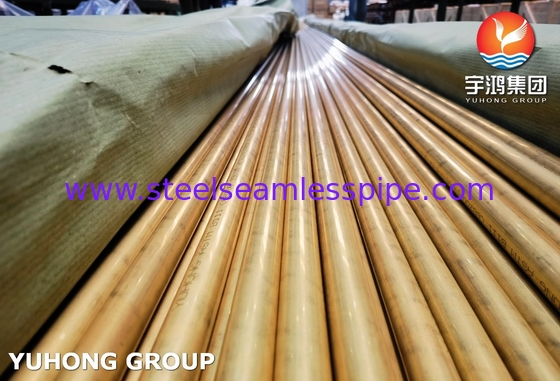

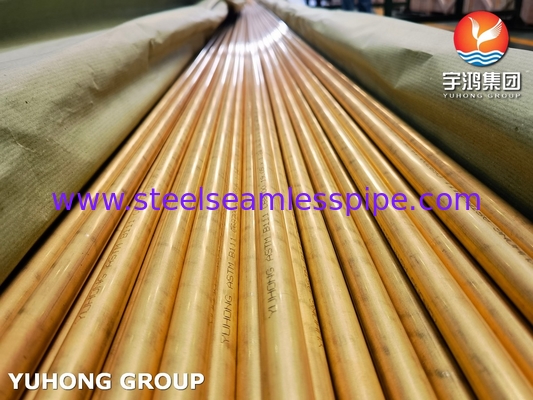

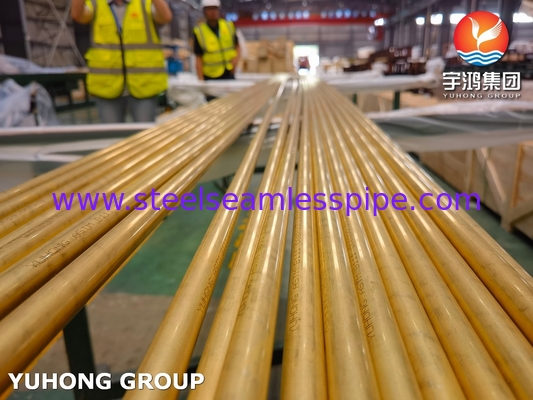

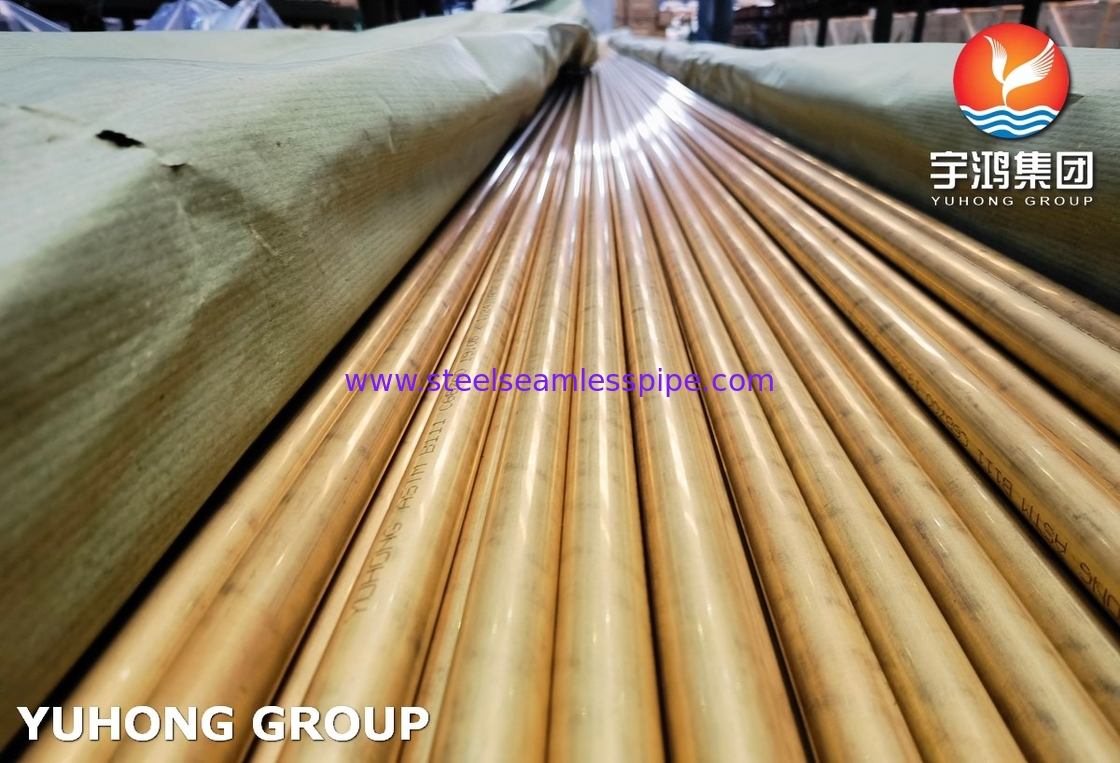

ASME SB111 C68700 O61 Tubo senza cuciture per condensatore ad alta temperatura di acqua di mare

ASME SB111i tubi senza cuciture sono comunemente utilizzati incondensatori ed evaporatori.

ASME SB111 C68700Qualità e composizione del materiale

-

Materiale di base, fornisce eccellente conduttività termica e resistenza meccanica, Cu:760,0-79,0%

-

Migliora la resistenza e la lavorabilità mantenendo al contempo la resistenza alla corrosione, Zn: Resto

-

Migliora la resistenza alla corrosione, in particolare nell'acqua di mare ad alta velocità, Al:10,8 2,5%

-

Aggiunge resistenza all'erosione e all'impatto, Fe:00,05 0,20%

-

Previene la disincinificazione, garantendo una durabilità a lungo termine nei sistemi idrici, in quanto:00,02 0.06%

-

Mantiene la lavorabilità; basso contenuto garantisce la conformità alle normative ambientali come RoHS, Pb:≤0,05%

ASME SB111 C68700Dimensioni e tolleranze del prodotto

1.Diametro esterno (OD)

Distanza/valore: 6 mm - 300 mm

Tolleranza: per OD ≤ 50 mm, la tolleranza è di ±0,05 mm; per OD > 50 mm, è di ±0,1 mm.

Nota: una tolleranza OD precisa garantisce la compatibilità negli scambiatori di calore e nei condensatori.

2Spessore della parete (WT)

Intervallo/valore: 0,5 mm - 10 mm

Tolleranza: ± 10% dello spessore nominale

Nota: lo spessore uniforme della parete garantisce prestazioni meccaniche e termiche costanti.

3. lunghezza

Distanza/valore: fino a 12 m

Tolleranza: ±5 mm per lunghezze fisse

Nota: può essere personalizzato per soddisfare i requisiti specifici del progetto.

4- Diritta.

Distanza/valore: ≤ 1 mm/m

Tolleranza: non specificamente contrassegnata

Nota: garantisce una facile installazione e allineamento durante il montaggio.

ASME SB111 C68700 Condizioni di consegna

- Finitura superficiale: liscia, brillante e priva di difetti quali graffi, buche o ossidazione.

- Pulizia: pulita internamente ed esternamente per rimuovere olio, grasso e altri residui.

- Imballaggio: confezionato con involucri di plastica protettivi o scatole di legno per evitare danni durante il trasporto.

- Trattamento termico: Fornito in condizione di ricottura, di riduzione della tensione o di estrazione, a seconda delle esigenze del cliente.

- Marcatura: I tubi sono contrassegnati con il nome della lega, le dimensioni e il numero del lotto per la tracciabilità.

- Personalizzazione: lunghezze, finiture o rivestimenti speciali (ad esempio anticorrosione) disponibili su richiesta.

ASME SB111 C68700 Caratteristiche di prestazione

1.Tensione alla trazione

Valore: 310 - 450 MPa. Fornisce una elevata resistenza meccanica, adatta a applicazioni impegnative.

2.Forza di rendimento

Valore: 105-220 MPa, resistenza sufficiente per sistemi a pressione moderata.

3- Allungamento.

Valore: ≥ 35%. Una buona duttilità consente di piegare, scatenare e modellare durante la fabbricazione.

4Conduttività termica

Valore: ~ 120 W/M·K Eccellente efficienza di trasferimento del calore, fondamentale per scambiatori di calore e condensatori.

5.Resistenza alla corrosione

Valore: eccellente nell'acqua di mare, altamente resistente alla desinficazione, all'impatto e alla bioinquinamento negli ambienti marini.

6.Resistenza all'erosione

Valore: elevato. Il contenuto di alluminio migliora la resistenza all'acqua ad alta velocità o ai flussi turbolenti.

7.Temperatura di funzionamento

Valore: fino a 300°C. Adatto per applicazioni industriali e marine ad alta temperatura.

8.Densità

Valore: ~ 8,53 g/cm3 densità standard per le leghe di ottone, garantendo un peso gestibile per gli impianti.

ASME SB111 C68700Certificazioni standard

- B111: Specifica standard per tubi condensatori senza saldature in rame e in lega di rame.

- EN 12451 europeo: norma per i tubi senza saldature di rame e di lega di rame per scambiatori di calore.

- ISO 19688: Norma internazionale per tubi senza saldature in lega di rame per scambiatori di calore.

- BS2871 Parte 3: Norma britannica per tubi senza saldature per scambiatori di calore e condensatori.

- Conformità RoHS:Restrizione delle sostanze pericolose, garantendo un tenore minimo di piombo per la sicurezza.

- NACE MR0175: Assicura l'idoneità per ambienti di servizio acidi in cui è richiesta resistenza alla corrosione da H2S.

- Rispetto del PED: conformità della direttiva sulle apparecchiature a pressione per i sistemi a pressione in Europa.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!