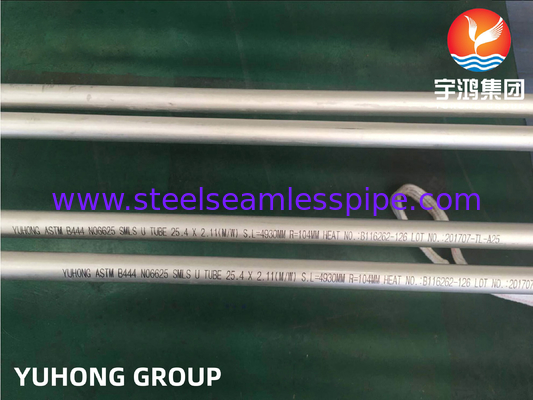

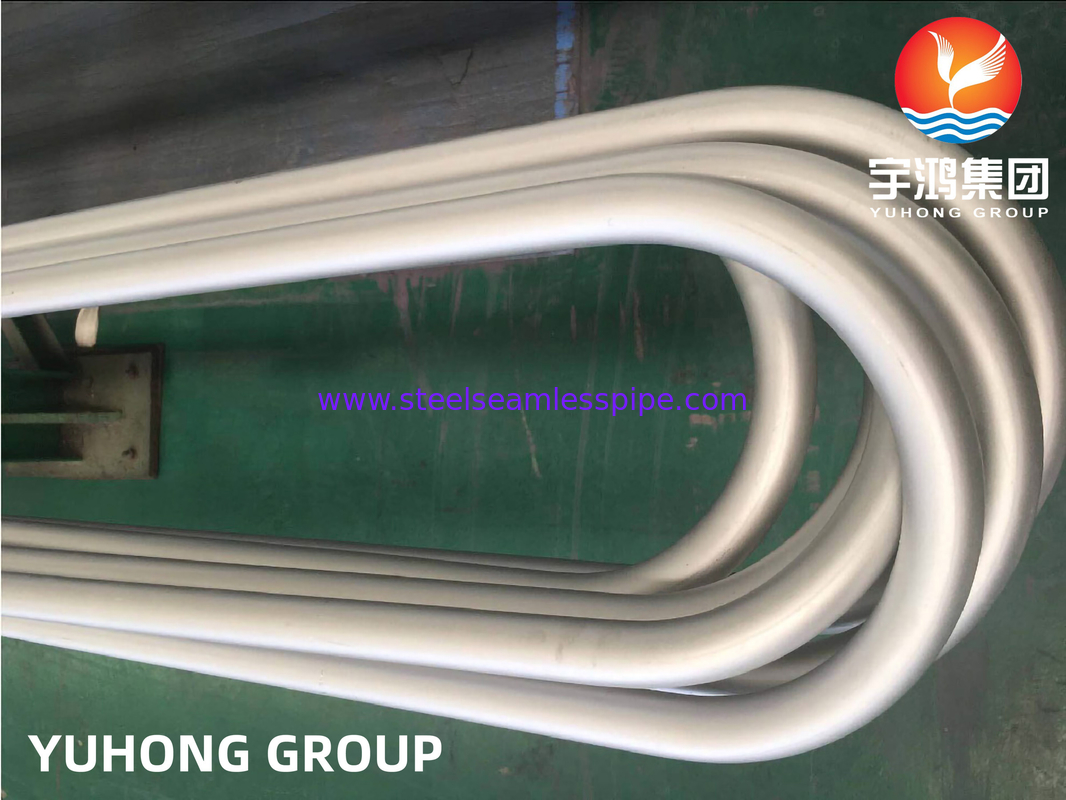

Inconel 625, Lega di nichel Tubo U senza cuciture ASTM B444 UNS NO8825 Per scambiatori di calore

L'ASTM B444 specifica i requisiti per i tubi e i tubi senza saldature in lega di nichel, con UNS N08825 (comunemente noto come Incoloy 825) come materiale ad alte prestazioni progettato per ambienti aggressivi.Questa lega combina un'eccellente resistenza alla corrosione e una resistenza meccanica, che lo rende adatto a applicazioni industriali molto impegnative.

Inconel 625 Tubo U senza cuciture Composizione:

Nickel (Ni): 38-46% (fornisce resistenza alla corrosione).

Cromo (Cr): 19,5-23,5% (migliora la resistenza all'ossidazione).

Ferro (Fe): Resto (metallo base).

Molibdeno (Mo): 2,5-3,5% (resiste alla corrosione da buche/fessure).

Rame (Cu): 1,5-3,0% (migliora la resistenza all'acido solforico).

Titanio (Ti): 0,6-1,2% (stabilizza contro la sensibilizzazione durante la saldatura).

Carbonio (C): ≤ 0,05% (minimizza le precipitazioni di carburo).

Altri elementi (Mn, Si, S) sono controllati a bassi livelli per prestazioni ottimali.

Inconel 625 Tubo U senza cuciture

Prodotti mediante estrusione o perforazione rotativa, i tubi senza cuciture garantiscono un'integrità e uniformità di pressione superiori, ideali per applicazioni ad elevato stress.miglioramento dell'affidabilità in ambienti corrosivi o ad alta pressione.

Inconel 625 Tubo U senza cuciture

Resistenza alla trazione: ≥ 586 MPa.

Capacità di accensione: ≥ 241 MPa.

Allungamento: ≥ 30% (assicura la duttilità).

Trattamento termico: soluzione anneolata a 925-1025°C seguita da raffreddamento rapido per ottimizzare la microstruttura.

Resistenza alla corrosione: eccelle sia in ambienti ossidanti (ad esempio, acido nitrico) che riducenti (ad esempio, acidi solforico, fosforico).e atmosfere marine.

Inconel 625 Tubo U senza cuciture

- Produzione di acido solforico: utilizzato nei concentratori di acido, nelle tubazioni e negli scambiatori di calore (resiste alla corrosione fino a una concentrazione del 40% a temperature elevate).

- Evaporatori di acido fosforico: gestiscono liquami caldi e altamente corrosivi durante la produzione di fertilizzanti.

- Produzione di solventi clorurati: Reattori e condensatori esposti a cloro, cloruri e acidi organici.

- Tubi sottomarini: linee di flusso e ombelici per l'iniezione di acqua di mare o il trasporto di idrocarburi corrosivi.

- Scambiatori di calore di raffinazione: tubi per preriscaldatori di petrolio greggio e unità di recupero dello zolfo (resistenti alla sulfidazione).

- Sistemi di raffreddamento dell'acqua di mare: condensatori e scambiatori di calore in impianti di desalinizzazione, navi e piattaforme offshore.

Inconel 625 Tubo U senza cuciture

Risponde alla norma ASTM B444 per i requisiti chimici, meccanici e dimensionali.

Compatibile con la norma ASME SB444 per uso in recipienti a pressione.

Le prove non distruttive (NDT) e idrostatiche garantiscono la qualità.

Inconel 625 tubo U senza cuciture

prestazioni superiori a temperature estreme (fino a 540°C).

La costruzione senza saldature aumenta la sicurezza nei sistemi ad alta pressione.

Versatile in ambienti corrosivi multifase.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!